When considering the size of artwork to suit caps, care must be taken to ensure that the cap is able to receive this artwork without production issues.

Items such as visors, military caps, "flexfit" caps and some brands and styles of caps have features that can limit the embroidery areas. These limitations do not always match a supplier's claimed maximum embroidery area.

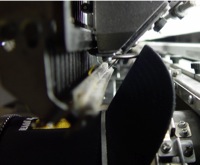

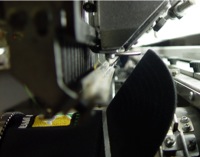

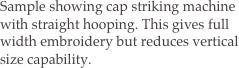

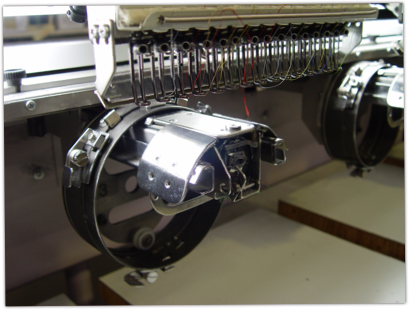

The cap attachment on an embroidery machine allows it to sew onto a cylindrical surface by converting the flat plane motion in the X direction to a rotational movement about the centre of the cylinder.

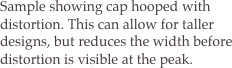

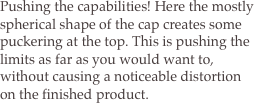

The cap front face is more or less a cylinder, conforming to a round face, however the further away from the peak you go, the cylinder becomes spherical, and reduces the relative width, causing distortion, and in worst cases, major puckering and interference with the machine arm.

Caps with a perpendicular peak also cause some size limitations as they restrict how close the machine can go to the peak of the cap.

Some wide brimmed hats also have limitations. These can be assessed from a pre-production sample.

Monday, 10 August 2009